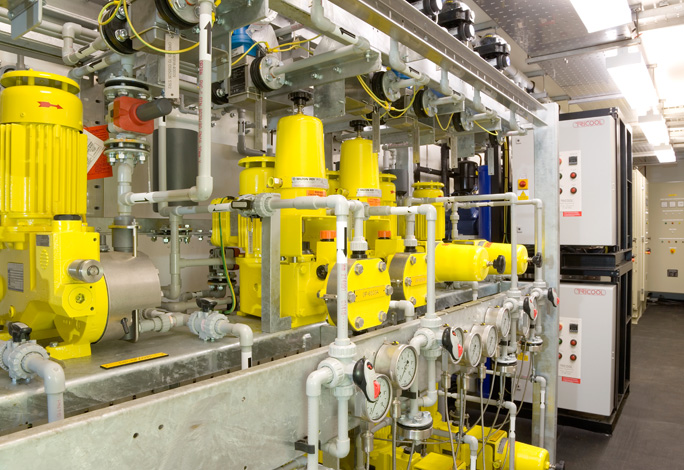

Cumberland’s NATCHLOR™ cells and systems are designed specifically for operation on artificial brine sources, i.e. food grade salt. These products and process are used extensively on potable water applications where the requirement for minimisation of disinfection by products (DBP’s) is paramount.

Any typical seawater analysis will contain salts which will react in the electrolysis process to form DBP’s such as bromide, which will convert to bromate. It is therefore not recommended to use hypochlorite generated from seawater in disinfection of drinking water circuits. In this instance Cumberland recommend our

NATCHLOR™ plants.

NATCHLOR™ systems are based on exactly the same principles s the

PANCLOR™ system although additional equipment is needed in the form of salt saturators, brine storage and pumping systems, brine dilution, measurement and control systems

NATCHLOR™ systems will produce hypochlorite at between 6000 – 9000 ppm

The Cumberland

NATCHLOR™ range is a range of onsite Hypochlorite generators, these generators are modular in construction thus far allowing flexibility in the size, and capacity tailored to the needs of the client.

There are many advantages to having a

NATCHLOR™ generator on site,

- On demand, on site production of sodium hypochlorite

- No, transportation, handling or storage of hazardous chemicals

- No dependency on bulk supplier deliveries

- Minimal space requirements

- Low risk assessment requirements

- Minimal maintenance requirements

- Low capital costs

- Low operating costs

- Low consumables usage

- Minimal disinfectant by-products

DOWNLOAD PRODUCT BROCHURE

Case studies